This is a production line!

Glass Sandblasting

SOLUTIONS

Get a Quote

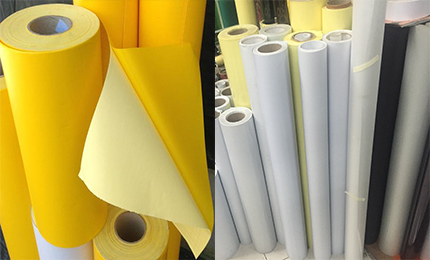

Film/Sticker

Lamination

The heatable and Pneumatic pressure system makes high efficiency and good quality.

The heatable roller is made out of silicone rubber, which can be heated up to 120oC. The glue film can be heated while laminating on the glass surface.

The high temperature and high pressure can ensure excellent lamination performances, high adhesive strength, no air bubbles, no wrinkles.

Film/Sticker

Cutting

The traditional method is to use a small size cutting plotter to cut the pattern on the vinyl protective film, then paste the film onto the glass for further processing.

Now, we totally changed the production process. With the Artcut machine, you paste the protective film on the glass first, and then cut the pattern directly on the film, then peel off the parts where the glass will be sandblasted.

Sandblasting

Process

Two types of sandblasting machines: Horizontal

Vertical

Horizontal type: No air-compressor, no nozzles, bulk production. The glass moves from one side to another side on the conveyor belt at a speed of 1 meter per minute.

Vertical type: Automatical and manual with air-compressor and nozzles.

OUR GLOBAL CLIENTS

Increasing every week